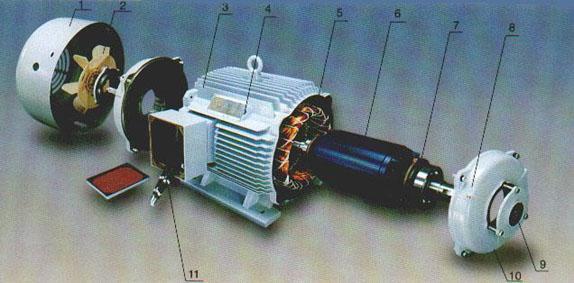

| 1.

Steel fan cover for optimum strength.

2. Small size,

high strength non-sparking fan reduces noise and enhances efficiency. Fan

is keyed to the shaft.

3. Heavy-duty

cast iron frame, end plated and conduit box.

4. Chromium-plated

copper nameplate with standard information on motor efficiency, wiring

diagram, bearing sizes etc.

5. Ultra-Shield

Plus TM 200 C inverter spike resistant magnet wire, high grade electromagnetic

steel stator, lower resistance and I2R losses, high efficiency design,

inverter rated insulation system.

6. Cast aluminium

rotor dynamically balanced, for reduced vibration and noise. The surface

is painted with a semigloss polyester finish.

7. Bearings

meet all standards. 143T-256T frame motors use double shielded ball bearings

while 284T frame and larger motors have greaseable bearings with bearing

caps to protect against entry of grease into the motor.

8. Lubrication

fittings on each end of motor (284T frame and larger). Lithium base grease

is used with range of -30C~+110C ambient temperature.

9. Neoprene

shafts slinger protects bearings by repelling moisture and other contaminants.

10. One-way,

corrosion resistant condensate drains to release condensation and moisture

from the housing.

11. Oversized

cast iron conduit box, double gaskets, box can be rotated in 90° increments.

NPT threaded entrance. Leads are extra long and permanently marked, 404T-405T

frame motors have 12 leads, suitable for wye-delta starting. |