COMMUTATORS FOR MOTORS

ISO9002 CERTIFICATED

From 1990,We are committed to fulfilling the commutator needs of motor manufacturers

worldwide.Today,we have succeeded in intergrating Patented Product Design,Cutting-edge Manufaturing Technology and Nationally Certified Quality Assurance System to manufacture commutators that can withstand some of the most demanding operating conditions;our core competency is in Mica-molded Segment-type Commutators,primarily,for the Automotive,Home Appliance and Power Tool Industries.

Our Objective is to Provide a Product Unique to your Needs by utilizing a custom product design geared to meet your application requirements,international grade oxygen-free high conductivity silver-copper(10oz.or more silver per ton) and asbestos-free phenolic molding compounds,state-of-the-art equipment,a constantly refined manufacturing process and a stringent quality assurance system.We will have the capacity to produce 25million commutators annually .

.Commutator Type

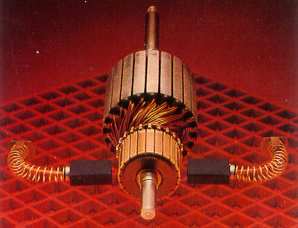

Tang-type Commutators

We provides highly reliable mica-molded segment-type tang commutators for applications in the home appliance and power tool industries.To meet the needs of high speed and current motors as in vacuum cleaners, we have the ability to provide reinforced ring tang commutators as well.

For automotive applications as in starter motors,we have developed a line of Mica-molded Riser-type commutators designed to withstand the rigorous environment in which such motors must operate. Riser-type Commentators

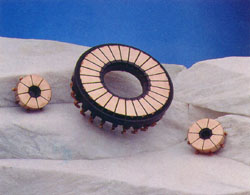

In addition to Tang and Riser type Commutators,we also makes planar type commutators for automotive applications as in automobile air conditioner motors. Planar-type Commutators