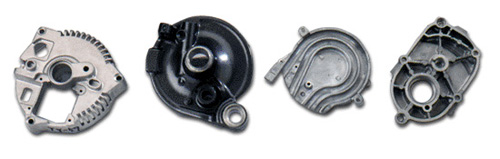

| Our Aluminium Die Casting factory

is a Chinese-Japanese joint firm manufacturing various aluminum die-casting

products and resin-molding products with ultra-modern equipment from Toshiba

and Japanese advanced die-casting technology. Chinese and Japanese first-class

engineers are charged with production management.

With Japanese 90's typical advanced melting

furnace, the company can liquefy and preserve the heat of liquid

aluminum to manufacture the aluminum die-casting products suitable for

differently required various aluminum materials. There are eight sets of

die-casting equipment from 250tons to 800tons in the company. With new

& special technology, it is easy to satisfy the customers' need of

qualified and multi-kind of products.

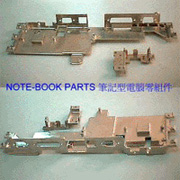

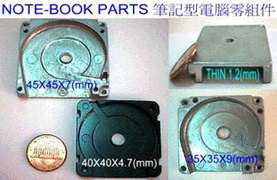

With the advanced Japanese molds, the company

can manufacture many kinds of qualified products in the extensive industry

like electric motor ,automobile, motorcycle, sewing machine, precision

machine, measuring equipment, office equipment etc..

There is strict quality control system

in the company, which includes strict control and inspection for every

production step to manufacture the qualified products. The company uses

the Optical Emission Spectrometer "OES-5500" manufactured by Japanese top-maker

SHIMAZU in 1990s'to analysis the chemical element of the aluminum alloy

rapidly and accurately.

Not only there is excellent production

system under ideal manufacturing line stepping up "5s" management, also

we design the products/molds/special-purpose manufacturing facilities with

CAD application. |